Product Detail

Pressing

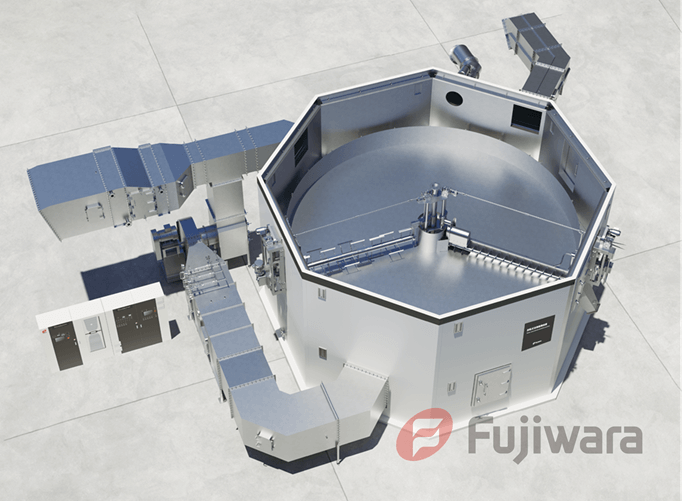

F-type Moromi press equipment

operation

quality

operation

■ Outline

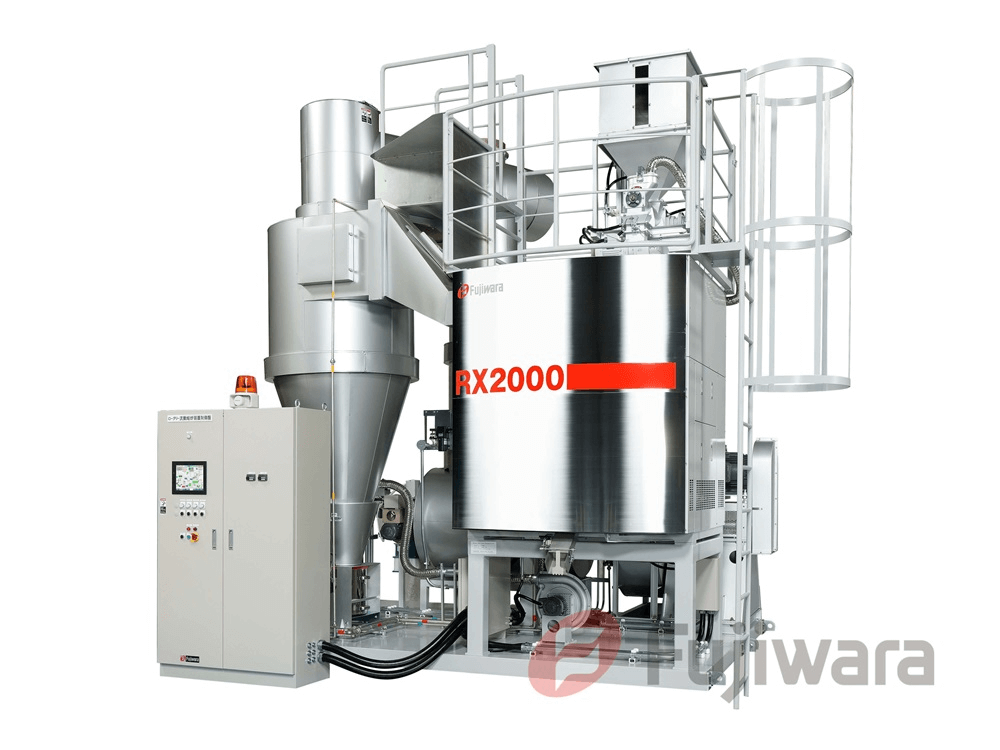

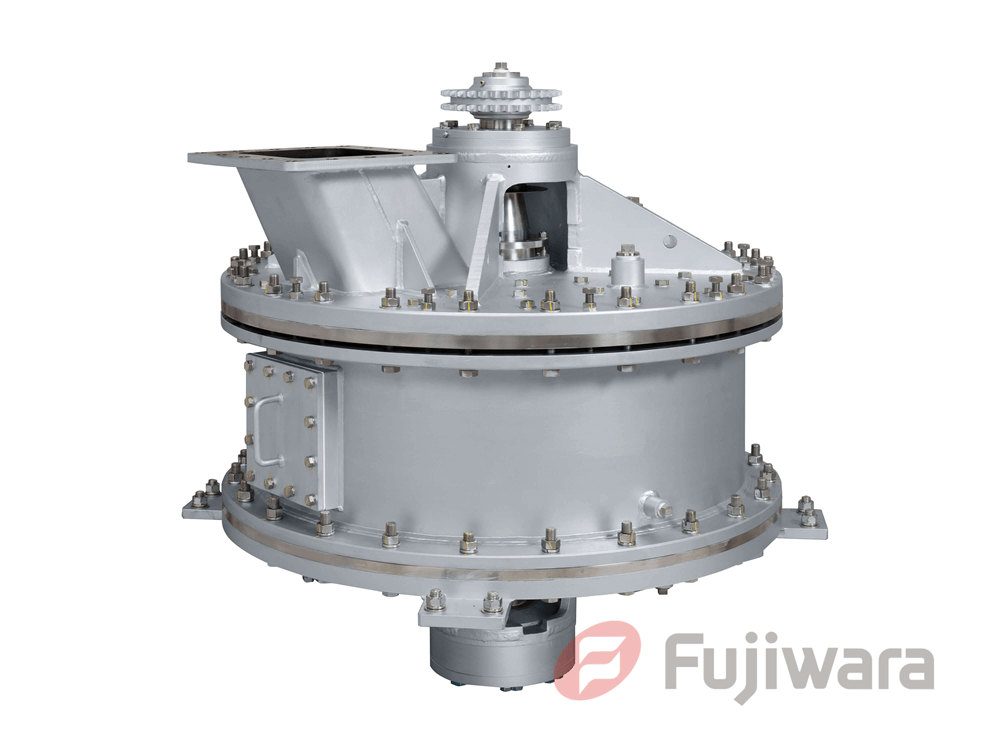

Automation and high quality have been realized in the pressing process of soy sauce brewing. Especially, various innovations based on long years of experience have been adopted for Moromi filling equipment.

■ Point

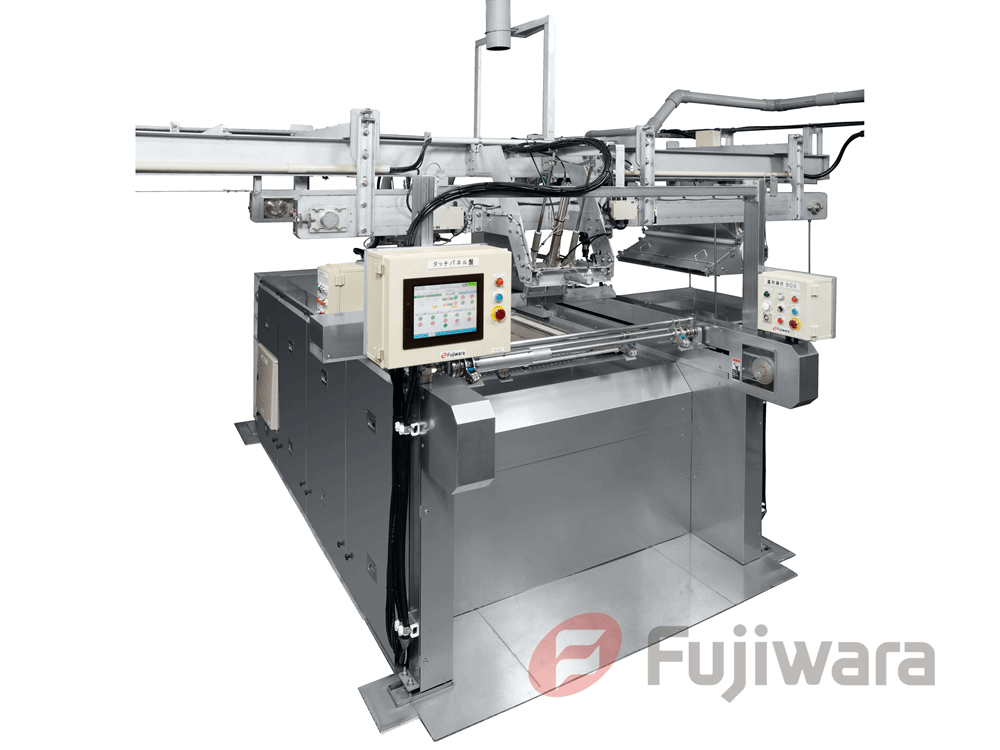

1. All the processes from Moromi filling to cleaning of a filter cloth, dewatering, alignment, and cake treatment have been fully systemized.

2. Minimized manpower

10kl/day - 15kl/day requires 1 worker for the entire process

20kl/day - 30kl/day requires 2 workers for the entire process

48kl/day - 72kl/day requires 2.5 workers for the entire process

3. Moromi filling and filter cloth folding processes have been fully unmanned, which was traditionally thought to be nearly impossible.

4. Easy operation

5. Pressing is program-controlled by a control device inside a computer, and ideal pressing can be done unattended day and night.

6. Since cleaning of a filter cloth and cage is fully controlled by a computer, water amount to be used is very small, and a burden of waste water treatment has been greatly reduced.

Related Words

■ Download Documents

■ Product Inquiries

The form is loading. Please wait a moment.

Inquiry

Inquiry