Product Detail

Roasting・Cooling

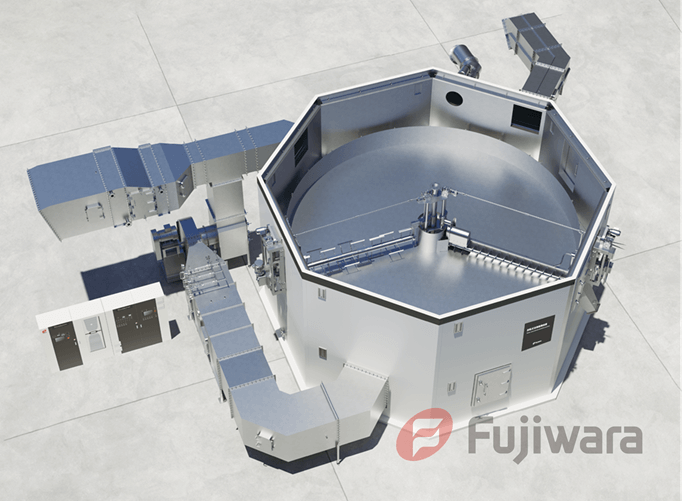

Rotary flow type roasting device

Hot Air Flow Saves Energy and Provides High Quality

quality

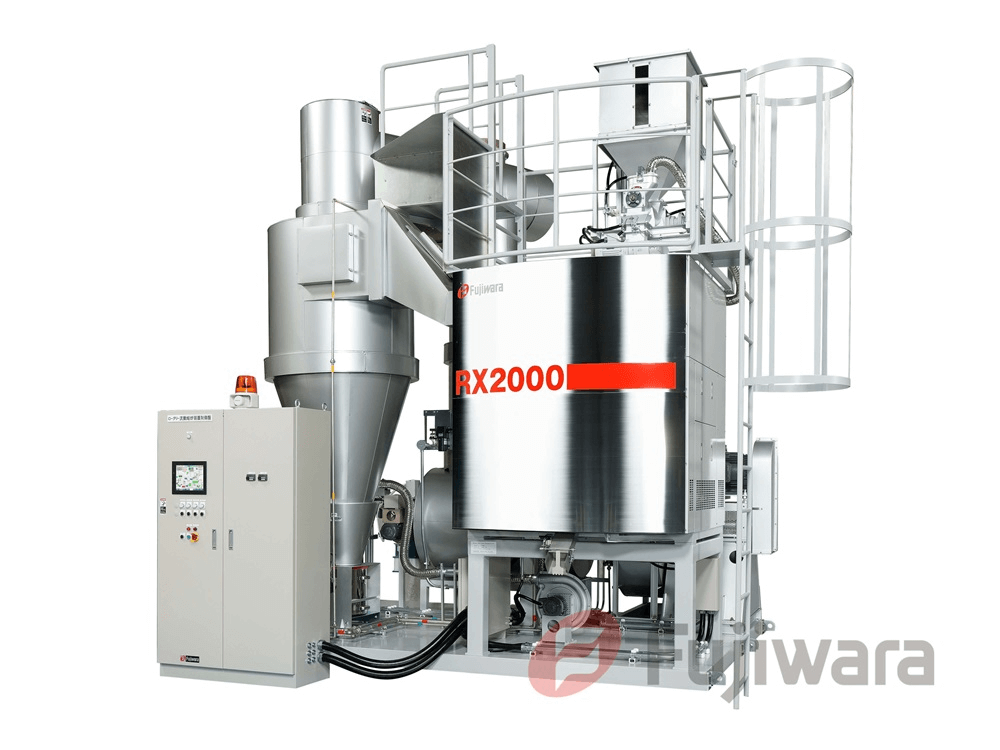

Operation

design

■ Outline

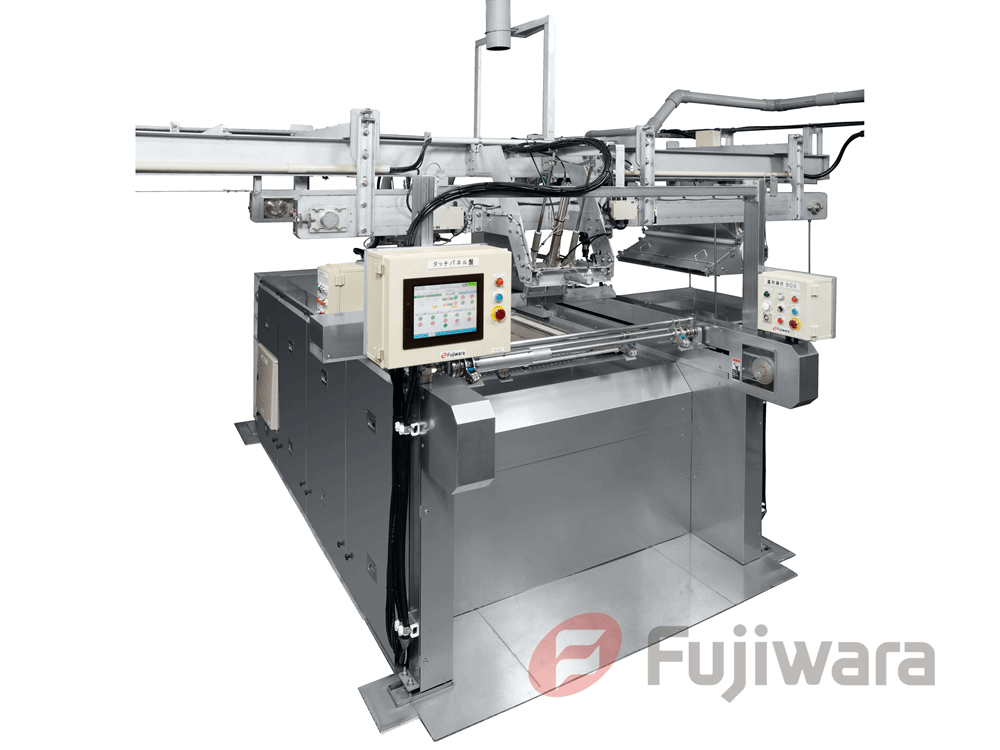

The rotary flow type roasting device blows hot air from below the continuously fed grain raw material layer to lift and fluidize the grain. Raw materials are heated rapidly by hot air while flowing, and roasted in a highly efficient, energy-saving, and hygienic manner.

Development involved thoroughly ascertaining the relationship between heating temperature and time.

As a result, for the first time in a hot-air flow roasting system, optimum conditions were obtained to achieve a high degree ofα-Amylase conversion of starch (degree of starch gelatinization) while uppressing burning and protein hyperdenaturation.

Fully automated continuous roasting contributes to a significant increase in productivity.

■ Point

1.No sand or other heating medium is used, to ensure that no foreign matter is mixed in with the raw

materials and maintain hygienic processing.

No damage to equipment in the following processes, and no need to collect sand and other substances.

2.Roasting in a fluidized state heats raw materials uniformly Consistent quality without uneven roasting.

3.Continuous roasting and fully automatic operation greatly improves productivity.

4.Direct control of roasting temperature (hot air temperature). Roasting conditions can be easily set

5.Raw materials are heated directly with hot air. Substantial energy savings provided by generating hot air using a circulation method.

6.Thorough insulation to prevent heat dissipation significantly improves the working environment

compared to conventional methods.

7.Safety is ensured by a water sprinkler function that prevents fire in the event of an operating

failure.

Related Words

■ Download Documents

■ Product Inquiries

The form is loading. Please wait a moment.

Inquiry

Inquiry