Product Detail

Pressure Steaming ・Cooling

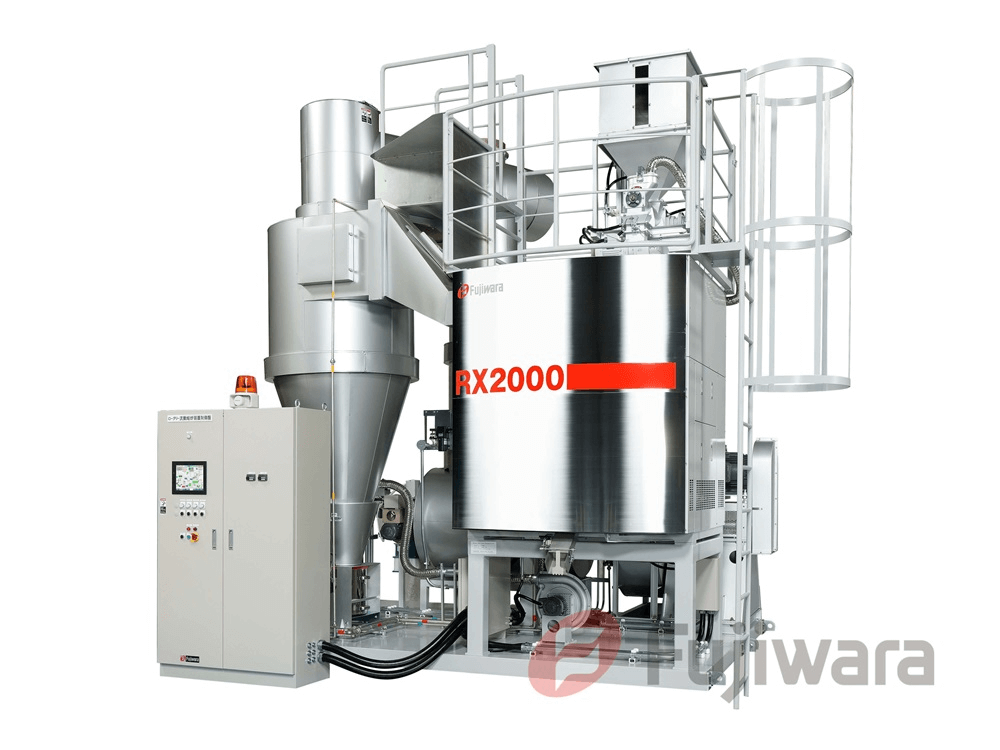

Continuous high pressure steaming equipment

Continuous Uniform Steaming for High Efficiency and High Quality

multi purposes

durability

Sanitation

■ Outline

Continuous high pressure steaming equipment was developed to continuously high-pressure steam brewing material such as defatted soybeans and whole round soybeans and it has been widely acclaimed to date. For processing of materials that require high-pressure steaming, such as defatted soybeans and whole round soybeans for soy sauce making, whole round soybeans for miso (bean paste) making, and rice for mirin (sweet cooking rice wine) making, this equipment is widely used.

Taking soy source as an example, material can be evenly processed during sprinkling, pre-heating, and high-pressure steaming, which realizes a high nitrogen usage rate combined with short-time process by high pressure.

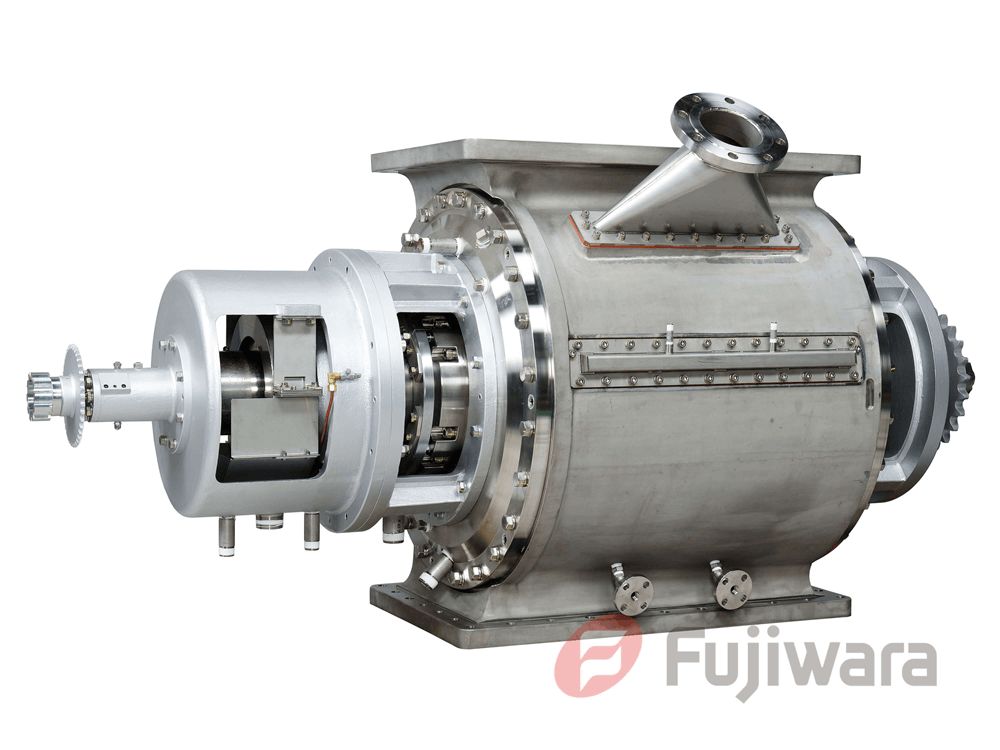

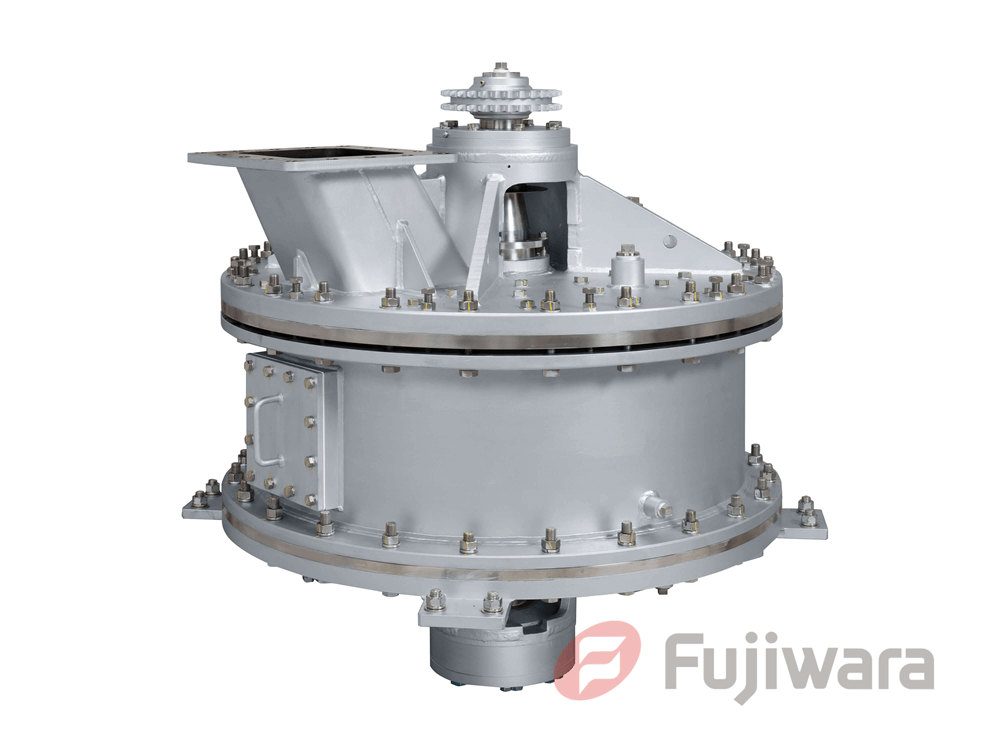

For a rotary valve, there are two types; a horizontal type and a vertical type depending on the intended use. The vertical type, in particular, has established a good reputation as a discharging rotary valve for processing whole round soybeans.

This equipment has made a large contribution to a high usage rate of material and cost saving. For such contribution, it has earned many prestigious prizes, such as a food industry technology award, an automated machine development award, and a director of Science and Technology Agency award. It also possesses many industrial rights, i.e. patent rights and utility model rights.

■ Point

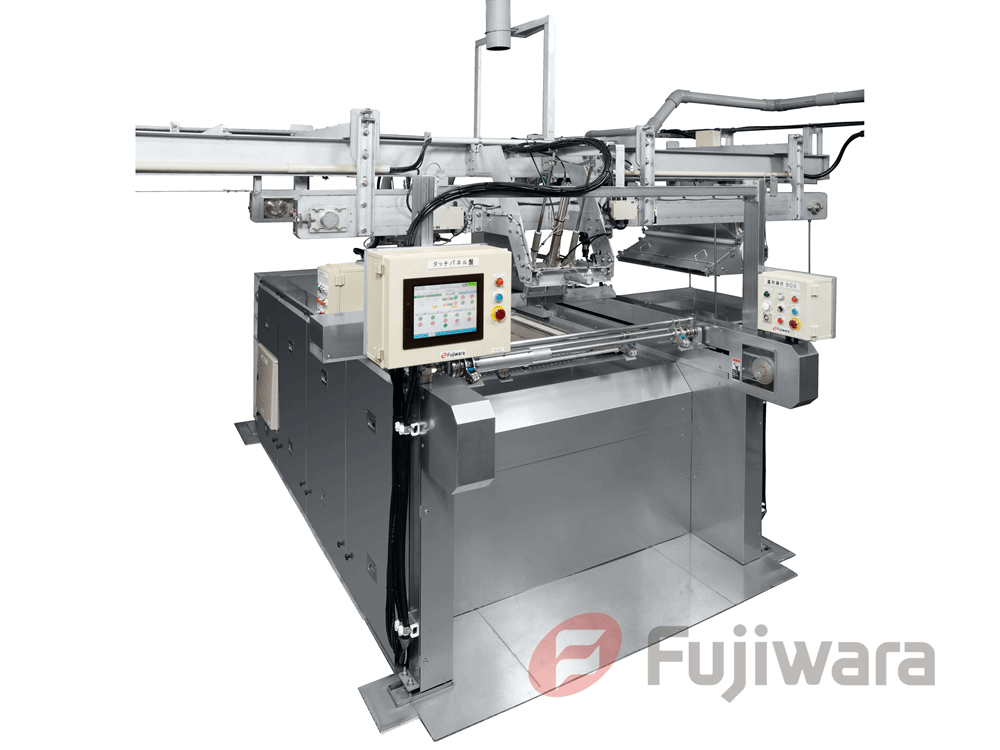

2. A continuous method has the following advantages;

- Significantly reduced working hours and improved efficiency

- Possible to cool material after steaming continuously and rapidly, which results in high quality

- Unattended operation has been realized by auto control

- Load of electricity and steam is more equalized than a batch type, which leads to a reduced boiler capacity, etc.

- Installation area is small for material throughput the equipment is capable of

3. A net conveyer method has the following advantages;

- Steaming detention time can be strictly kept.

- No material damage, high-quality steaming

- Especially, whole round soybeans are not kneaded.

- Material being transported on the net conveyer is accumulated without being pressed, so the steaming condition for each piece of material can be the same.

- Drain generated inside the can wall does not go into material.

4. About rotary valve

- There are two types; a horizontal type and a vertical type depending on the intended use

- When processing whole round soy beans by the vertical type, crushing from the impact when soybeans are discharged rarely occurs.

- About the horizontal type

* Great sealability by a noncontact small gap sealing, and high durability

* Small gap between the rotor and casing is automatically adjusted.

* Certain and smooth material transporting is realized by rotor water-cooling

and a material adherence preventing mechanism

* Therefore, cleaning after operation is very easy

5. Cleaning and checking can be done completely

As both ends of the steaming can be opened fully, the inside can be cleaned completely, and checking/inspection/repair are easy.

Characteristics in the case of handling defatted soybeans for soy sauce;

- Sprinkling, pre-heating, and high-pressure steaming can be done evenly and completely for every piece of material in each process, which realizes a high nitrogen usage rate and high quality combined with short-time process by high pressure.

- Space-saving equipment with shortened detention time and improved efficiency

- Energy-saving system realized by rotary valve’s high sealability, and also by using rotary valve’s cooling water for sprinkling.

Related Words

■ Download Documents

■ Product Inquiries

The form is loading. Please wait a moment.

Inquiry

Inquiry