Product Detail

Grain Washing・Washing・Soaking (Rice, Barley, Soybean, etc)

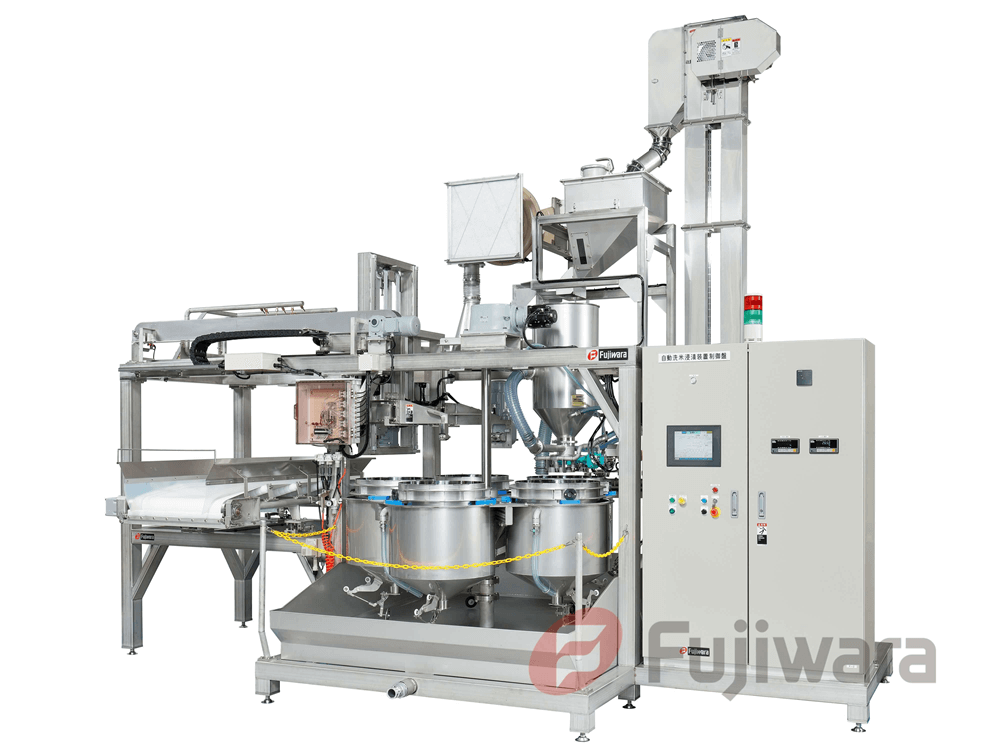

Automatic rice washing & soaking equipment Pro-5&Pro-3

Continuous washing and soaking of highly polished white rice

Batch Process

Absorption Rate

■ Outline

Traditionally, the washing and soaking process of highly polished rice used for Ginjo Sake (quality sake brewed from the finest rice) has required a lot of time and effort. Time for washing and soaking had to be determined each time. Therefore, a development of equipment that can wash and soak rice with a targeted water absorption has been much anticipated. Automatic rice washing & soaking equipment is an epoch-making equipment that can handle measurement/washing/rinsing/soaking of rice, forced removal of water on the rice surface, automatic calculation of water absorption rate, and discharge of soaked rice in a batch process. At the same time, it can figure out the water absorption rate of rice based on the weight measurement before and after the water absorption, and feed back the information to control the water absorption time and stable the water absorption rate.

■ Point

1. 30kg continuous batch process

2. Able to handle polished white rice of 35 – 65% (3 – 20 min.). Maximum capacity is 600kg/hr.

3. Complete rice washing by water stream and air bubbles

4. Water removal by showering/rinsing after rice washing and by an air blower after soaking

5. Function of data accumulation per batch or per lot is available.

6. Soaked time can be automatically adjusted by measuring the water absorption ratio.

Related Words

■ Customers Comment

Tsukasabotan Brewery Co.,Ltd. Chief brewer Toru Asano

The "rotary automatic rice washing and soaking machine" rinses rice perfectly and reaches the very percentage of water the rice should absorb.

Interview >>

■ Download Documents

■ Product Inquiries

The form is loading. Please wait a moment.

Inquiry

Inquiry