Product Detail

Solid State Cultivation (Koji Making)

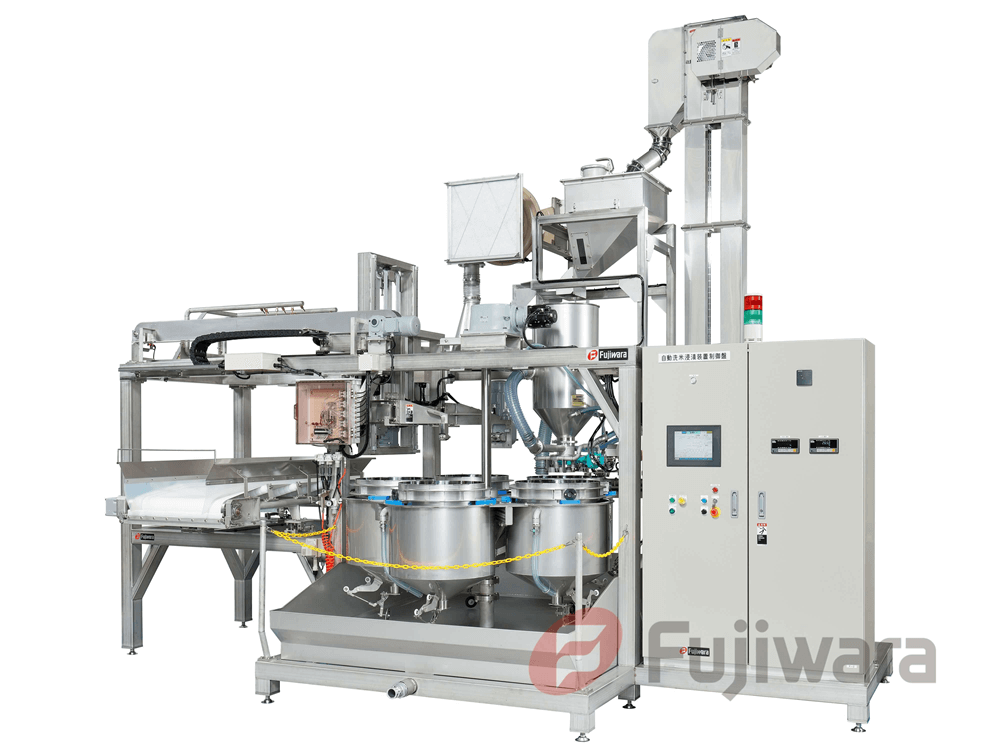

VEX type non-airflow ginjo Koji making equipment

Automated Production of High-Quality Ginjo and Daiginjo Koji

Breweryʼs Vision

Operation

■ Outline

Koji for Ginjyosyu requires high quality. Traditionally, about 3cm of koji was heaped and made (Futa koji method) by hand work. In developing non-airflow Ginjyo Koji making equipment, we have applied the concept of this Futa koji method and set the heaping thickness at 6cm, then discharge moisture vapor almost evenly from the top surface and bottom surface of koji layer to control the product temperature by latent heat of the moisture vapor. By using a functional fabric, ePTFE laminate (made by Japan Gore Tex Inc.), and also with a concept of water vapor partial pressure, we have made it possible for the moisture vapor discharging amount to be automatically controlled. There is no air flow inside the space surrounded by ePTFE laminate, which can provide perfect conditions for making high-quality and consistent-quality koji.

■ Point

1. Koji is accumulated for 6cm on the net conveyer surrounded by ePTFE laminate, and evaporate the water from both the top surface and the bottom surface in a non airflow state.

2. Due to non-airflow Koji making, high-quality and consistent-quality koji suited for ginjo is made.

3. Moisture evaporation amount from koji is controlled by ePTFE laminate and the concept of water vapor partial pressure

4. By adopting a vector temperature control method, product temperature is automatically controlled according to the temperature pattern entered on the screen.

5. By adopting a self-propelled turner, a completely unattended operation during koji making is possible.

6. ePTFE laminate is placed on the net conveyer to prevent the net from becoming dirty, and when ePTFE laminate is removed, the equipment is open and cleaning is easy.

7. ePTFE laminate is used for the pre-culture equipment as well to realize high quality and automation.

■Column

・Filtering and Powder Sterilization Technology

・Ginjo Sake

Related Words

■ Customers Comment

Tsukasabotan Brewery Co.,Ltd. Chief brewer Toru Asano

I love the simplicity of VEX. It consists of a few parts, and the idea applied to the machine is also simple, based on the traditional way of koji production. I can experiment various styles. That’s another thing I like about VEX.

Interview >>

Kunimare Sake Brewery Co., Ltd. Manufacturing Group, Section Manager, Yusuke SUGANO

Because VEX is controlled based on a pre-input program, temperature control and turning are done automatically. Thanks to the machine, we were able to significantly reduce our workload, including night and weekend work.

Interview >>

■ Download Documents

■ Product Inquiries

The form is loading. Please wait a moment.

Inquiry

Inquiry