Product Detail

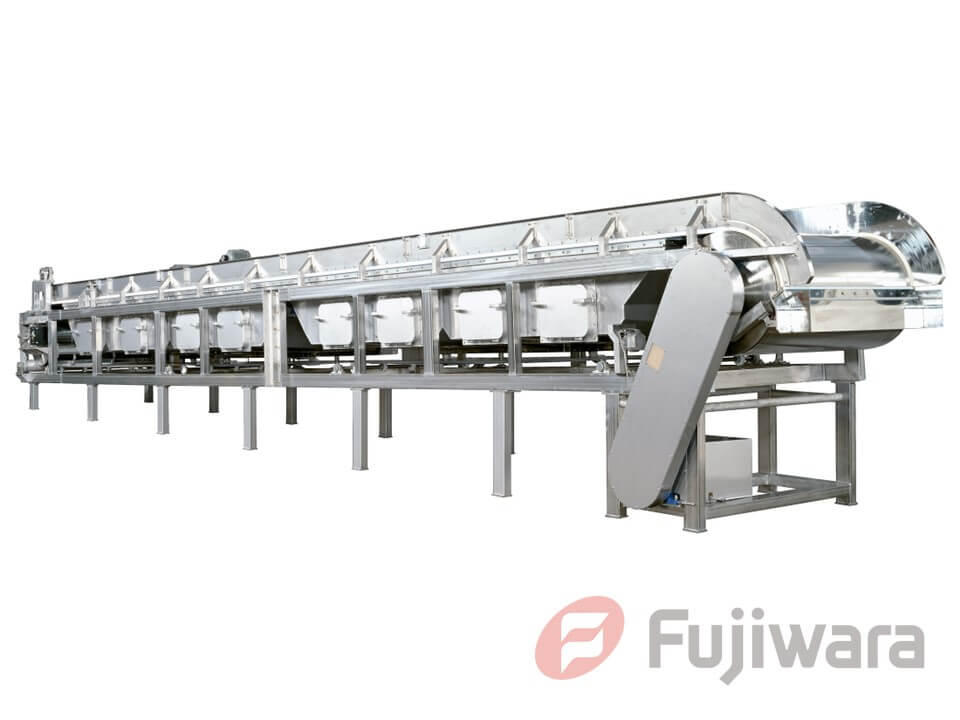

Non Pressure Steaming ・Cooling/Pressure Steaming ・Cooling

Upward flow type continuous cooling equipment

sanitation

saving

cooling effect

■ Outline

For the conventional air blowing method from above to down, material is compressed by air pressure, and fine particle materials, etc. are crushed into the belt surface to cause clogging. Therefore, a specified amount of air cannot be sent, which results in a degraded cooling effect. To drastically improve the cooling effect, we changed the air blowing method from down to above (upward flow type). By this change, the effective belt area has been reduced by 50% (compared to the conventional type) for soybeans and defatted soybeans. Number of crushers has been reduced as well and the entire equipment became space-saving. Also, clean air through a filter provides improved sanitation.

■ Point

1. Improved sanitation and washing performance by a simple and space-saving structure of the equipment.

2. Inside of the air channel and air blower can always stay clean with the upward flow method.

3. Improved washing performance with the stainless-steel belt. Contamination by bacterium during operation has also been reduced significantly.

4. Automatic cleaning device is useful to prevent contamination and also to save cleaning work after operations.

5. Air is sterilized by an air filter to minimize contamination of materials by bacterium.

6. As outside air is brought in for air blowing, inside of the room has a negative pressure, which can avoid gathering bugs or foreign materials. Exhaust ventilation is done outdoors by a hood and duct, so there is no dew condensation inside the room.

7. Temperature control function (optional) can stable the heaping temperature.

Related Words

■ Product Inquiries

The form is loading. Please wait a moment.