Product Detail

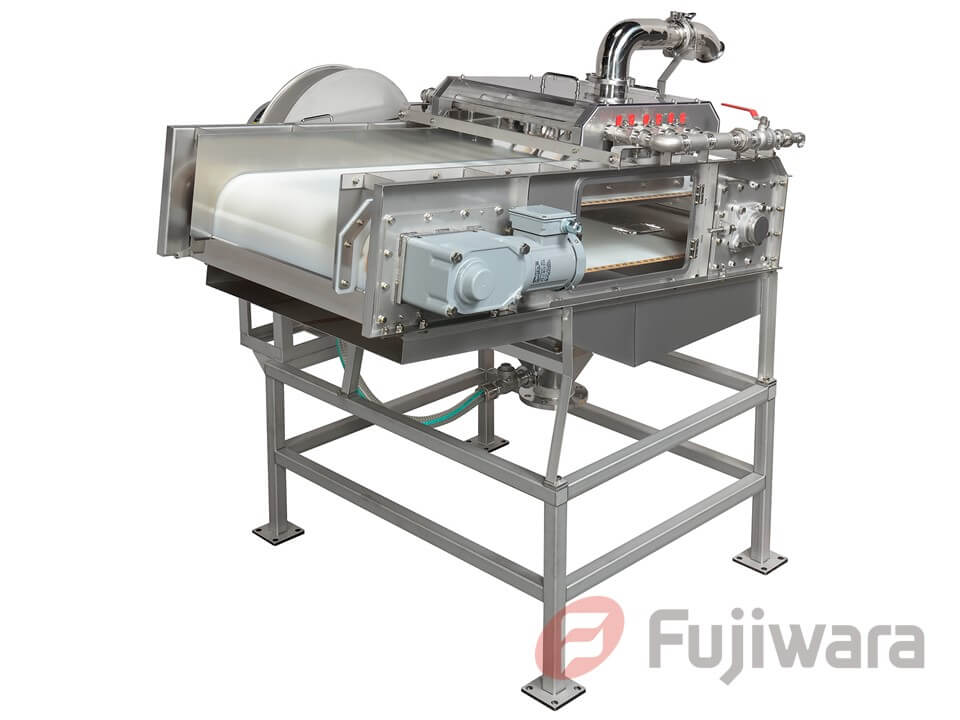

Grain Washing・Washing・Soaking (Rice, Barley, Soybean, etc)

Soaking tank for highly polished rice

Provides Soaking with Reduced Uneven Water Absorption

in short time period

soaked rice

■ Outline

Now that polishing rate of rice is becoming higher, the importance of soaking process has been recognized. It is not too much to say that the soaking & water separating process determines the quality of the subsequent steaming, cooling, and koji making. So, we have developed an epoch-making Soaking tank for highly polished rice. As it can take the water flow speed into consideration and supply/discharge water in a short period of time, we have received many favorable responses that the tank has solved all of the problems that the existing tanks had.

■ Point

1. Perforated bottom inside the tank makes the discharging area bigger and discharging time shorter.

2. Perforated bottom is slightly inclined, which makes it easier for water on the perforated bottom to be separated easily during soaking.

3. A special bridge-preventing structure makes it smoother to discharge soaked rice.

4. Perforated bottom turns up during washing and the back side of the perforated bottom can be washed completely.

5. Almost no manpower is required by automating the processes of supplying/discharging water and discharging soaked rice.

6. There is curving in the corner of the square shape, so discharging can be done almost without leaving any rice.

Related Words

■ Customers Comment

Kamotsuru Brewery Co.,Ltd. Chief Master Brewer Kohji Tomoyasu

■ Download Documents

■ Product Inquiries

The form is loading. Please wait a moment.

Inquiry

Inquiry