Product Detail

Non Pressure Steaming ・Cooling

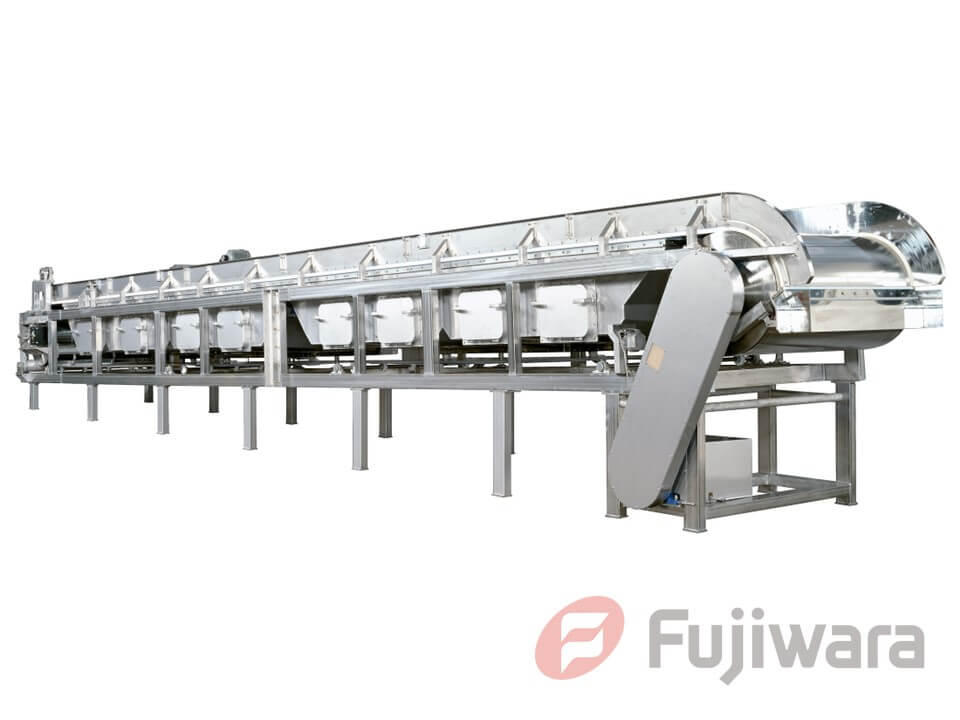

Steel belt type continuous steaming equipment

be changed freely

durability

Clean

■ Outline

The steel belt-type continuous steaming equipment achieves high efficiency and energy savings with minimal steaming inconsistencies through fluid analysis.

Its steel belt design prevents raw materials from clogging, and the automatic cleaning brush ensures excellent hygiene.

The steaming conditions can be easily controlled, as the steaming time can be adjusted by setting the belt speed.

However, some issues still remain.

In particular, cleaning the mesh surface and condensation in the side jacket sections remain significant challenges.

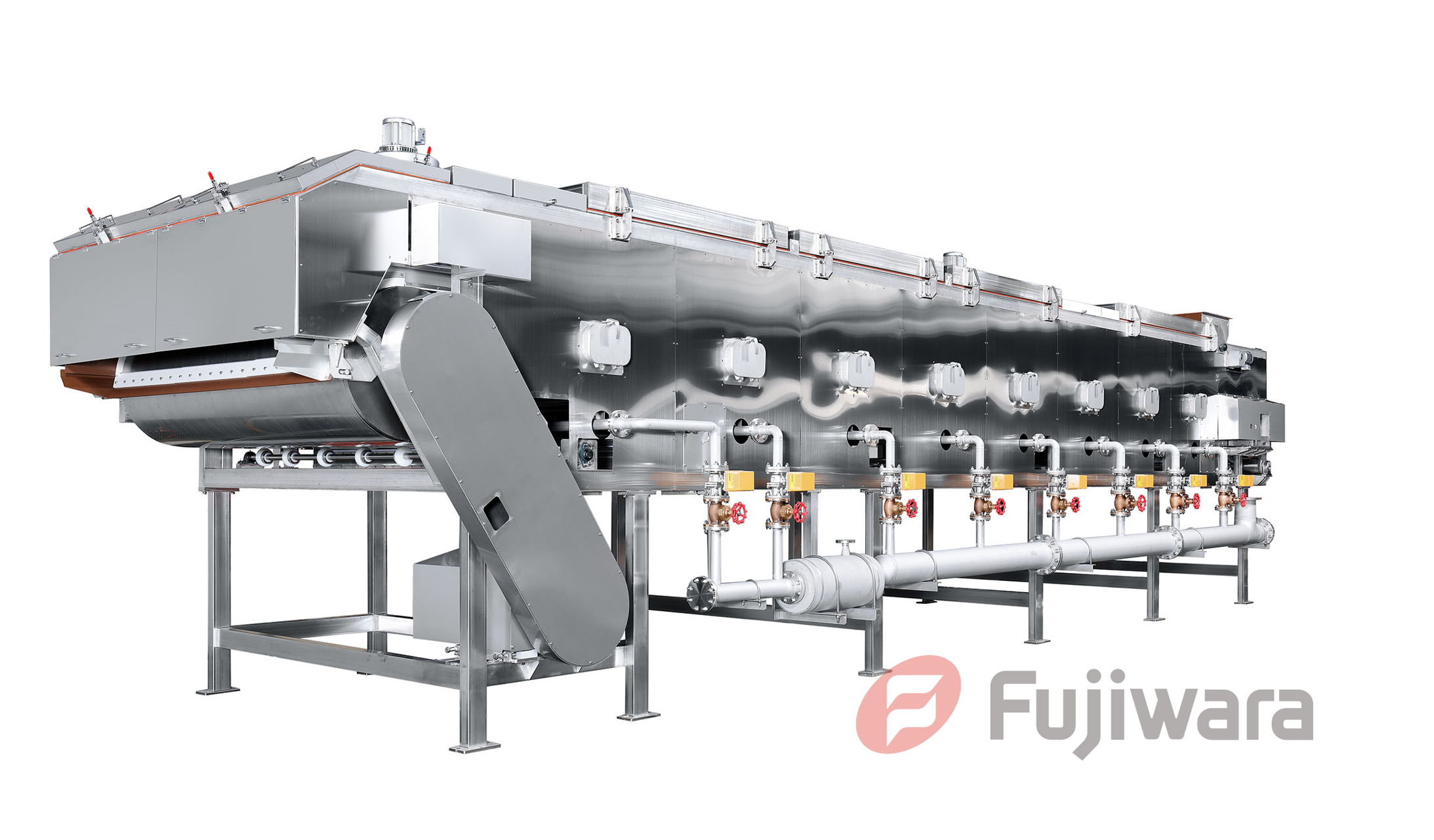

To address these issues and enhance the overall performance, we have made improvements and successfully developed a groundbreaking horizontal steel belt-type continuous steaming equipment.

■ Point

1. High Efficiency & Energy Saving

- Steam supply to the steam chamber is automatically reduced when no raw materials are passing through.

2. Condensation Prevention

- The sidewalls and ceiling doors feature an insulating structure to prevent condensation from dripping onto the raw materials.

3. Prevention of Uneven Steaming

- By subdividing the steam chamber and ensuring uniform raw material thickness, short paths of steam flow are prevented.

4. Visualization

- A steam flow meter allows numerical management of steam consumption during operation.

5. Sterilization

- The equipment can be used not only for steaming food but also for sterilization purposes.

6. Easily Adjustable Raw Material Input Volume

7. Freely Adjustable Steaming Time Settings

8. Digital Display of Steamed Rice Position After Input

9. Superior Durability with No Tearing or Stretching of the Steel Belt

10. Lid Opening and Closing Options: Air Cylinder or Handle Operation

11. Automatic Control of Steam Pressure and Injection

Related Words

■ Product Inquiries

The form is loading. Please wait a moment.

Inquiry

Inquiry